BP Oman Enhances Workforce Facility Operations with eFACiLiTY’s Facility Management System for Labour & Workforce Camps

BP is a leading global energy company in the oil & gas sector, operating in more than 70 countries. In Oman, BP operates from Muscat and is the operator of Block 61 (“Khazzan Makarem”). It is one of the Middle East’s largest tight gas projects, producing around 1.5 bcf/day and meeting around 35% of the country’s gas demand. In addition to oil and gas, BP is also investing in renewable energy initiatives such as green hydrogen and has contributed over $30 million to social and community development projects in Oman.

Business Requirements

BP Oman manages a wide range of critical assets and large spare parts inventories across its oil & gas camp. These facilities house a significant workforce, making it essential to ensure their smooth operation for safety, compliance, and overall workforce efficiency. However, BP Oman did not have a facility management system for labour & workforce camps in place. A centralised facility management system, like a CAFM, was required to manage maintenance activities, asset information, inventory, procurement, and service requests at scale.

This gap resulted in several operational challenges:

- Maintenance Execution Gaps: Maintenance activities were largely managed without a structured Maintenance Management Software. This was limiting visibility into planned maintenance schedules, work execution status, and asset history. This further led to reactive maintenance practices, increasing unplanned downtime and impacting asset reliability.

- Limited Asset and Inventory Visibility: Spare parts were tracked manually without a centralised asset management software. This led to stockouts and overstocking. The visibility over inventories linked to critical equipment was not optimal, causing delays in critical repairs.

- Slow Procurement Cycles: Manual purchase order creation and tracking created procurement bottlenecks, slowing maintenance schedules and extending equipment downtime.

- Inefficient Helpdesk Operations: The helpdesk is key to safety and compliance. At BP Oman, requests were logged manually using disconnected tools, making it hard to track, prioritise, and resolve issues — increasing safety and compliance risks.

Solution

BP Oman, committed to safety, compliance, and operational excellence, partnered with Masaken Al Raha, a facility management services provider and subsidiary of Como WLL in Kuwait and Oman.

Leveraging its experience in implementing IWMS & CAFM solutions with eFACiLiTY®, Masaken Al Raha selected the eFACiLiTY® EAM/CMMS and Helpdesk Module for BP Oman.

The eFACiLiTY® CAFM software provided BP Oman with a unified Work Order Management System. It integrates maintenance management, asset tracking, inventory control, procurement workflows, and helpdesk operations within a single digital platform.

This integrated approach enabled BP Oman to standardise maintenance execution, improve asset and inventory visibility, streamline procurement processes, and establish a structured helpdesk—without disrupting ongoing operations.

Benefits

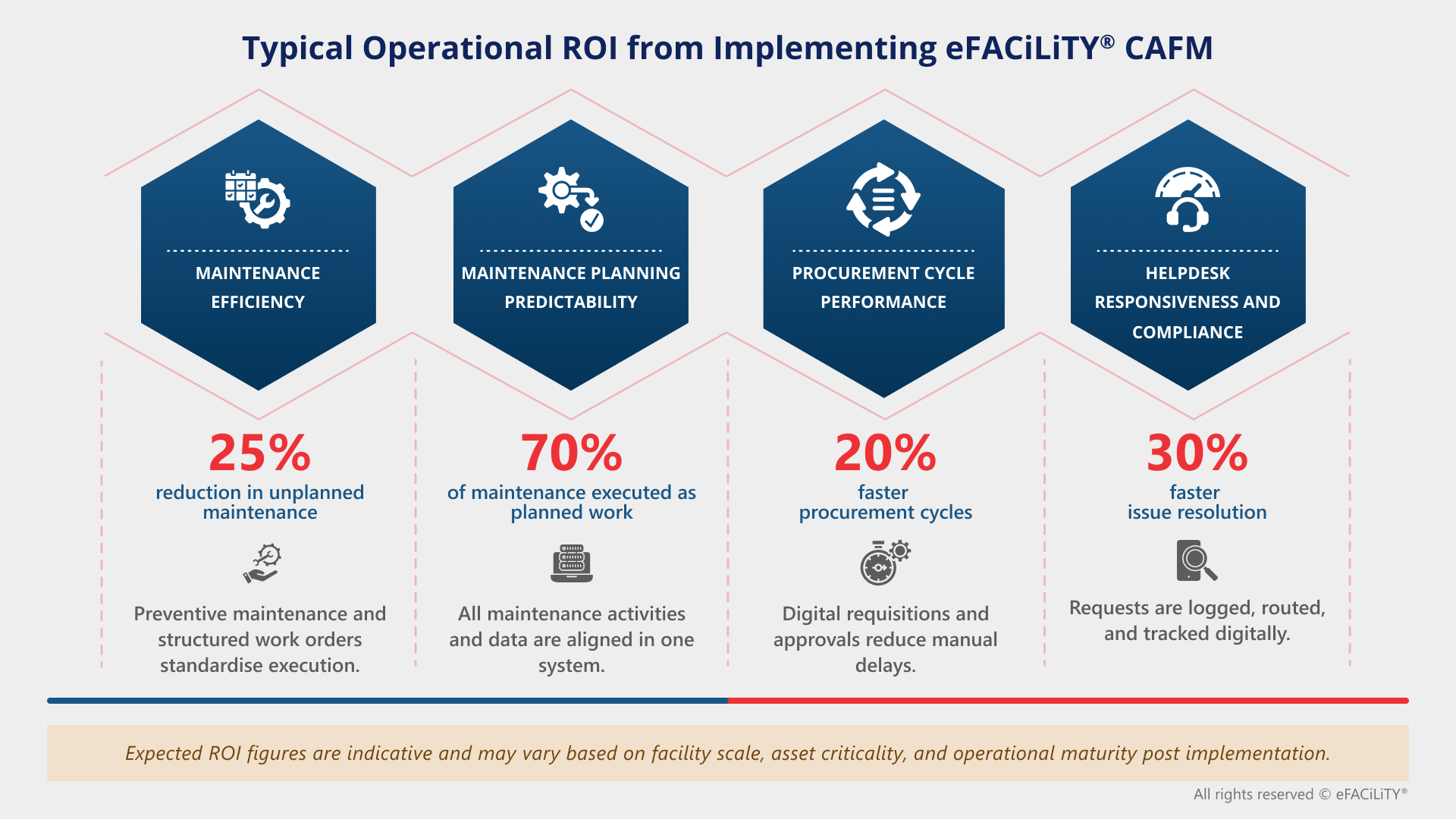

With eFACiLiTY® fully deployed, BP Oman realized significant improvements across maintenance, inventory, procurement, and service operations:

- Structured Preventive Maintenance Execution: Automated maintenance schedules enabled proactive planning and prioritised work order execution. Maintenance teams received clearly defined tasks with associated checklists, safety instructions, and required spares. This supports a shift from reactive maintenance to planned maintenance, improving overall asset reliability.

- Centralised Asset & Inventory Management: Over 1 Lakh assets are now managed within a single system, providing complete visibility into asset condition, maintenance history, and lifecycle costs. Integrated inventory tracking linked spare parts directly to assets, helping prevent stock shortages and excess inventory.

- Streamlined Procurement and Inventory Accuracy: Automated purchase order workflows and goods receipt validations reduced procurement cycle times and eliminated discrepancies between ordered and delivered items. This ensured the timely availability of spares and improved inventory accuracy, keeping maintenance activities on schedule.

- Improved Helpdesk Responsiveness and Accountability: The digital helpdesk enabled automated request logging, categorisation, and routing. BP Oman now efficiently manages 800+ service requests per month, improving response times, accountability, and service quality across facilities.

Conclusion: Building Resilience Through Digital Facility Management

BP Oman’s adoption of eFACiLiTY® demonstrates how a global leader in the oil & gas industry can modernise maintenance and helpdesk operations with a facility management system for labour & workforce camps.

By leveraging advanced CAFM software, they have streamlined operations, improved efficiency and ensured better management of critical assets, inventory, and service requests in these key facilities.

This move highlights that effective facility management is not only about improving efficiency but also about building long-term resilience and sustainability.

Experience a smarter maintenance management system for oil and gas, seamless helpdesk management, and operational excellence with the leading facility management software.

Ask for a Demo to see how eFACiLiTY® can transform your operations.